How to choose a suitable infrared heating lamp?

Today, infrared heating lamps are widely used in industry, and their heating history has been in the industry for decades. The traditional heating lamp heating method tends to greatly reduce the working efficiency of the assembly line due to the low heating efficiency. Today, the introduction of infrared heating lamps has greatly accelerated the production efficiency of the industry. In fact, different fields in the industry have different heating needs. So how can you choose the most suitable heating lamp for you?

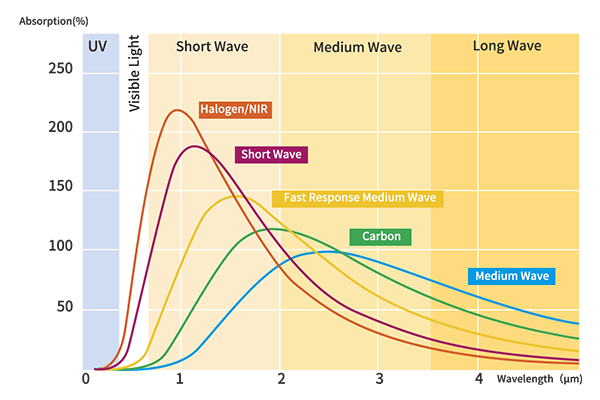

In fact, in the whole heating process, only when the wavelength of the infrared rays radiated by the infrared heating lamp is consistent with the wavelength absorbed by the heated object, the heated object can absorb a large amount of red and infrared rays, so as to achieve the purpose of heating, and the heating rate is can be greatly improved. Therefore, when choosing an infrared heating lamp, you should choose an appropriate wavelength and match the wavelength as much as possible with the wavelength that can be absorbed by the heated object, so as to maximize the heating rate and choose the most suitable heating lamp.

Second, it is also necessary to determine whether to use a coating on the outside of the tube. In fact, when the heating direction of the product is fixed, choosing to add a layer outside the lamp is conducive to better transfer of the energy carried by infrared rays to the heated object, saving energy consumption and making the overall heating efficiency faster. Today, there are two kinds of coatings on the market, and the choice of the coating also needs to be selected according to different product characteristics. The first is the semi-gold-plated reflective layer, which can generally work normally at temperatures below 600 degrees. The other semi-white reflective layer can normally perform its heating work in a high temperature environment.